KIETEK IS MATERIAL HANDLING

LOCKS

CAM LOC

Product Specifications

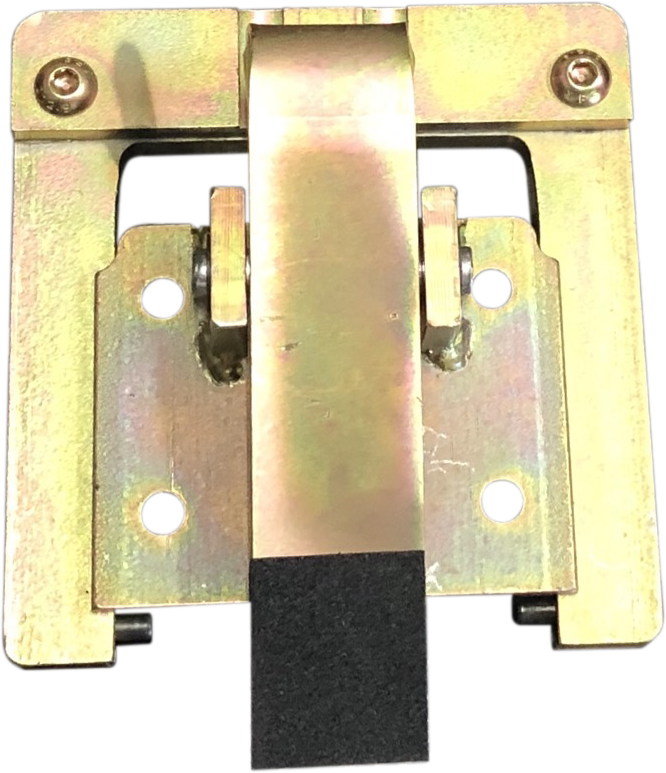

Placed on lifts and deck edges for the automatic resetting once a container has been pushed from a dolly onto a ball, caster or roller system. The lock resets after the container moves over the top and restrains the container from falling off.

To release a container, simply step on the top of the lock, depressing it until it locks down, allowing the container to traverse over the top. After the container has cleared, the lock automatically resets. NOTE: The locks are designed as a restraint, not to be confused with a stop.

FLIP LOC

PIN LOC

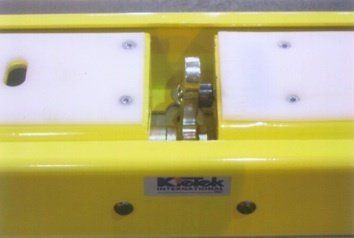

SLAM LOC

A motion-activated lock to restrain containers in workstations. This lock is best suited for containers parked in tight locations, where there isn’t enough space to walk between them to set a Pin or Flip Loc. The Slam Loc requires minimal obstruction clearance for workers as they load and unload containers.

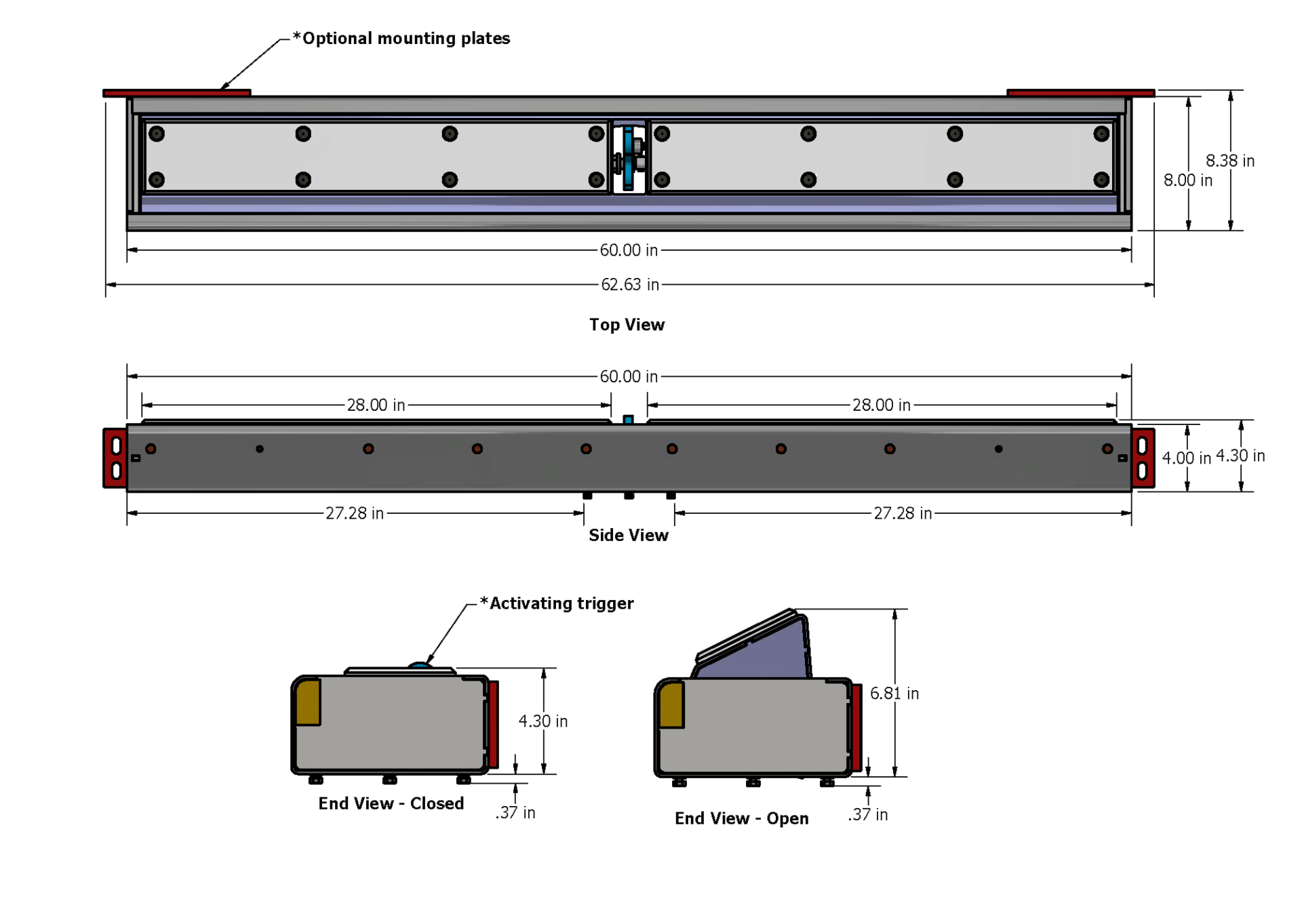

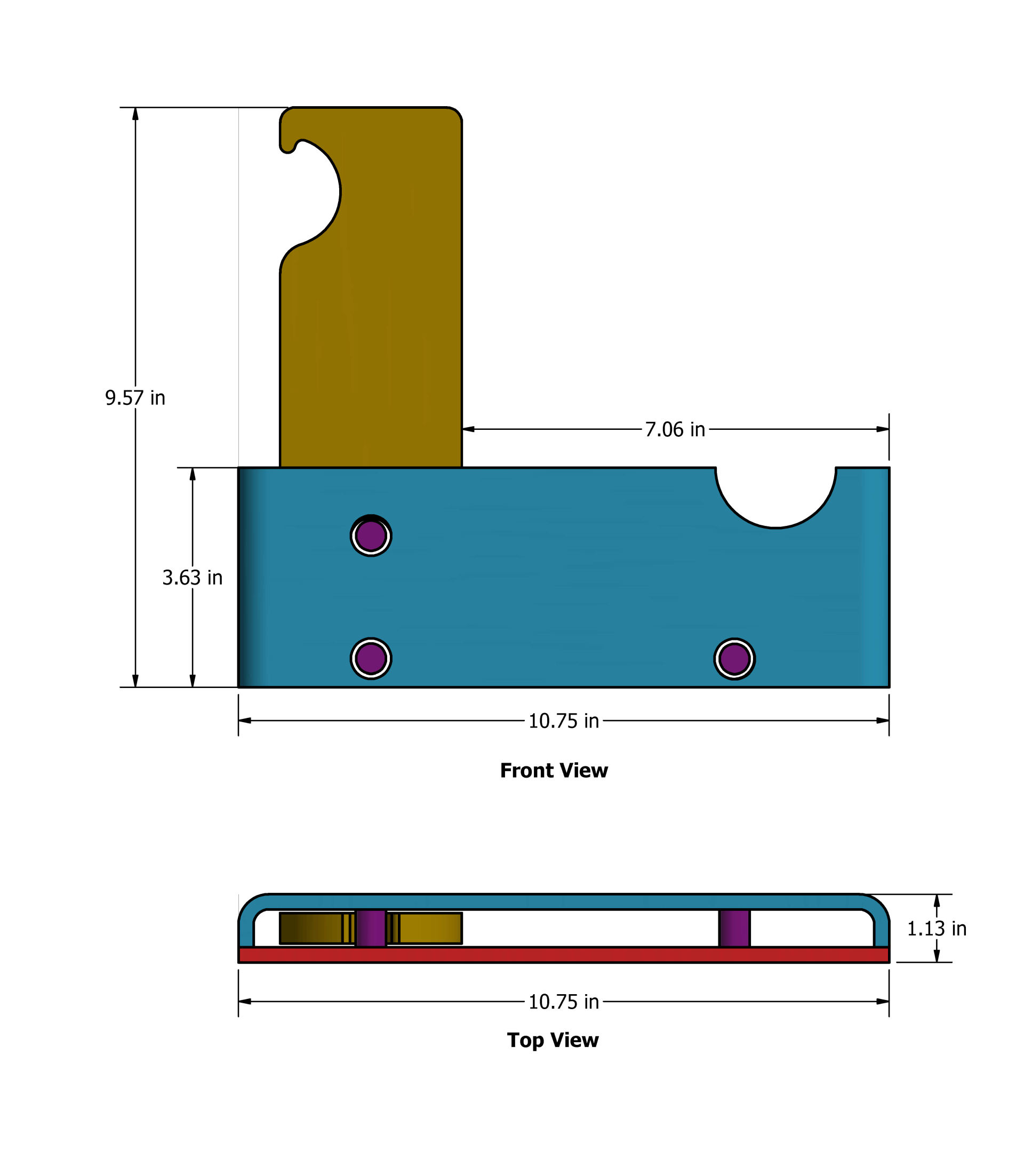

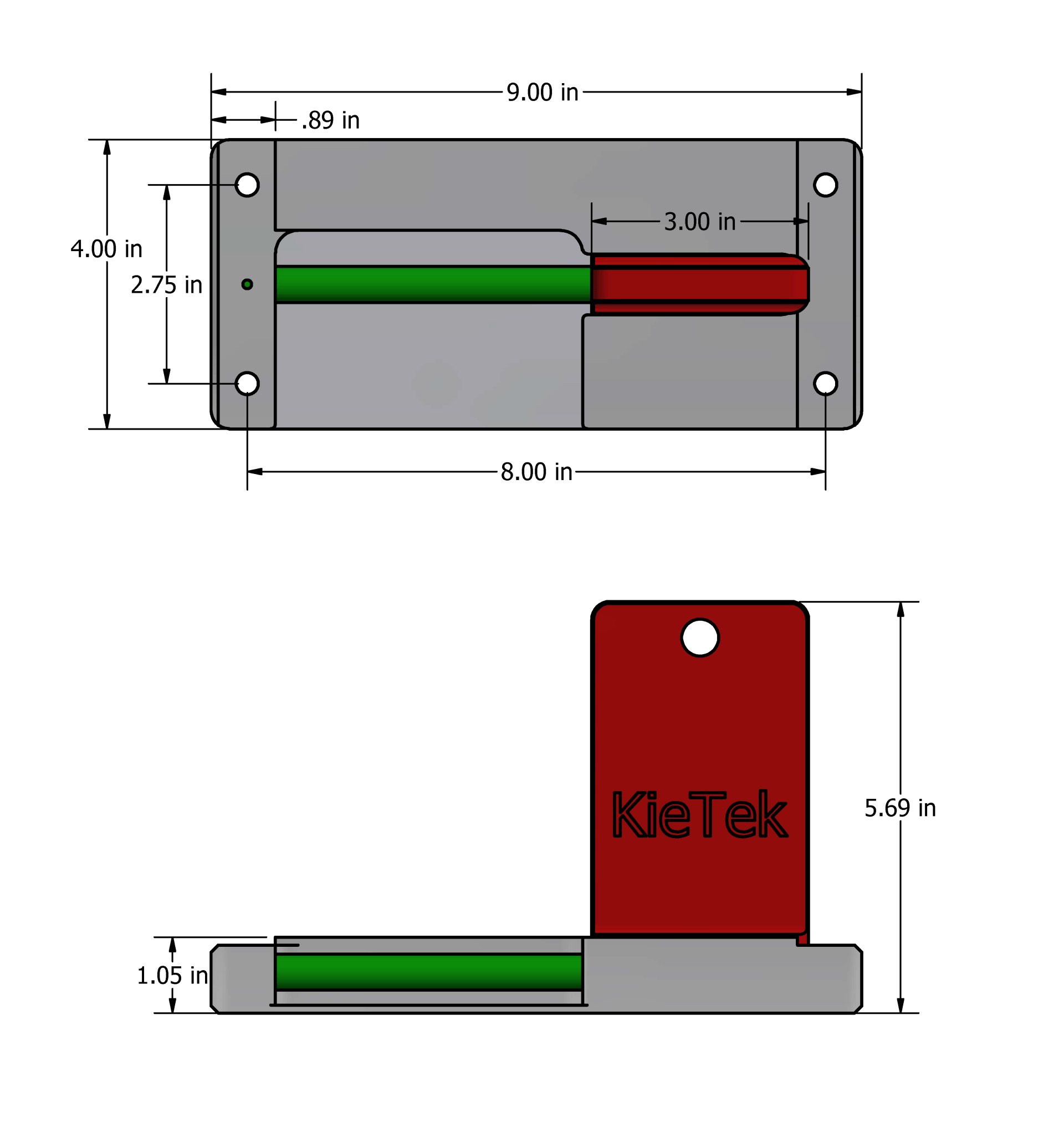

STEP LOC (SLIM LOC)

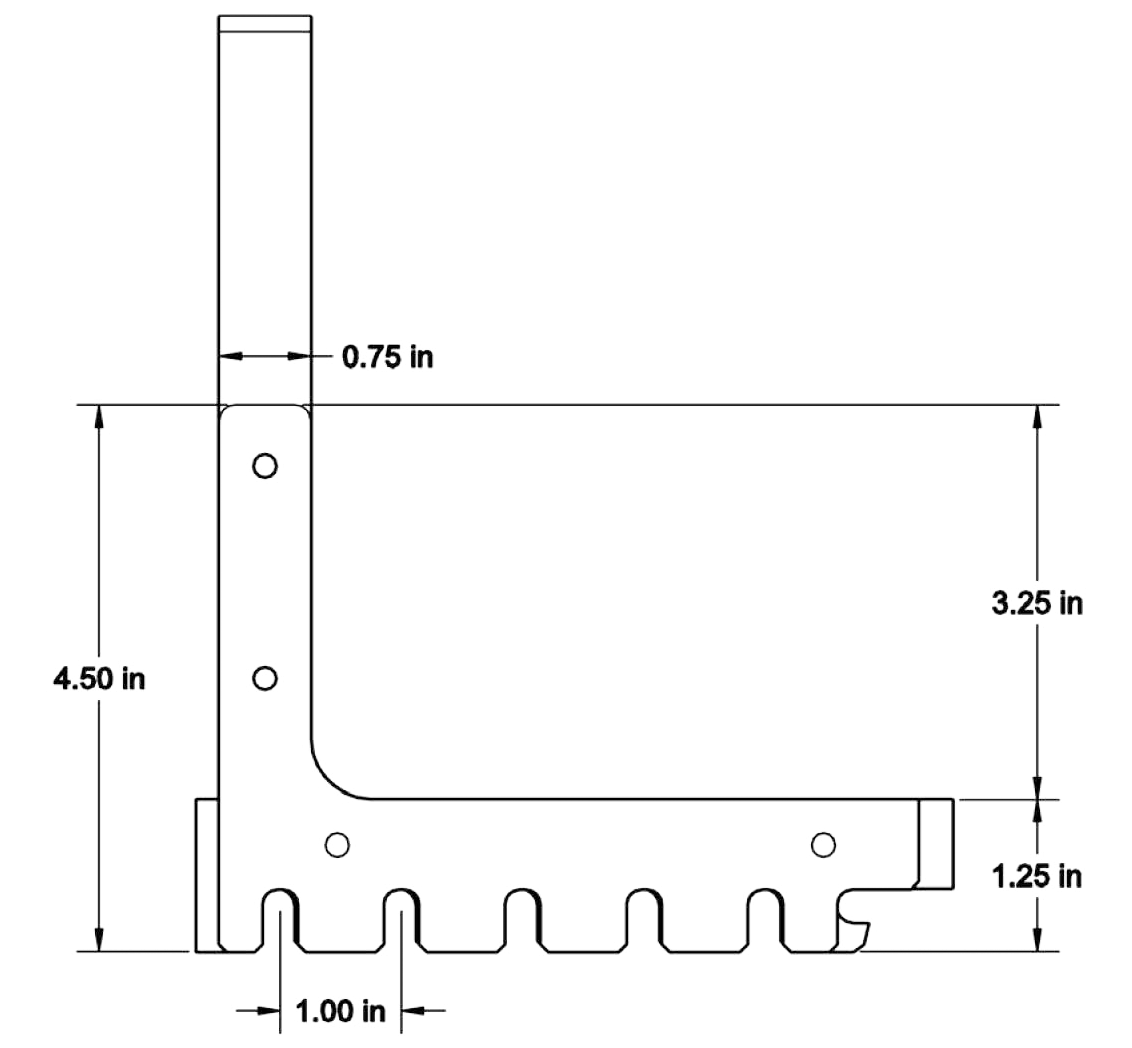

The newest lock we offer, which we also manufacture, is the Step Loc. It’s used in our trailer and van roller bed systems. We named it the Step Loc because you install and release it with your foot. It attaches to steel pins in a ladder tray that’s secured to the floor of the trailer or van. Containers, pallets and bulk freight can be locked in one-inch increments from the rear door to the nose of the trailer (including refrigerated trailers). For vans, one or two locks are used at the rear of the vehicle. For trailers, the locks are used in two tracks, as needed, to retain the load. A cargo strap is used to retain any freight that needs to fit tight against the back door.

Fiberglass T-LOC

Fits in the perforations of a Fiberglass Panel. The holes are spaced 2" by 2" squares spread throughout the Fiberglass Panel. The Fiberglass T-Loc can be placed within the 2" x 2" square mesh and moved around the whole fiberglass panel. This makes locking in any sized pallet or container anywhere on the panel.

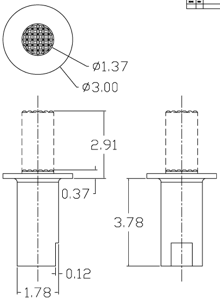

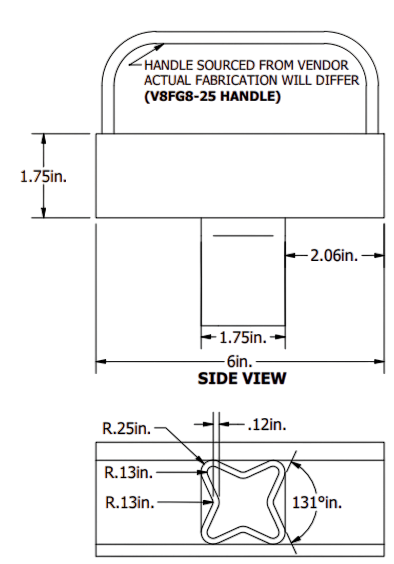

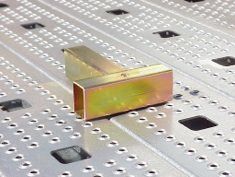

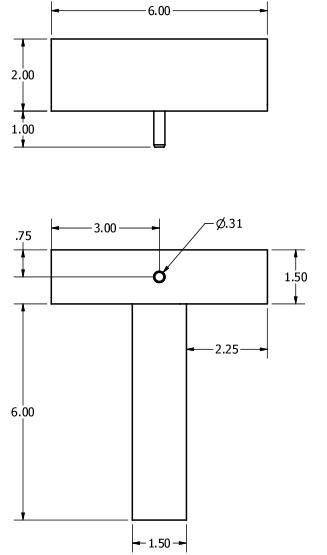

T-LOC

Fits in the perforations of a plank deck. The holes are spaced 1” apart across each plank and 1-1/2” apart lengthwise on each plank. This is the best alternative to locate a container or pallet anywhere on a plank deck system and contain it. The 5/16” x 3-1/4” locking pin protrudes 1-1/4” through the framework. The pin is hardened metal, rounded on the end for easier insertion in the traction hole. The T-Loc is manufactured as a 1-1/2” x 2” rectangular tube. It’s 6” wide x 7-1/2” long, with a 5/16” pin, and is plated in yellow zinc.

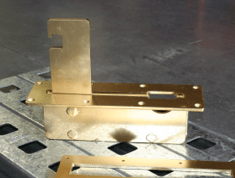

TRAILER FLIP LOC

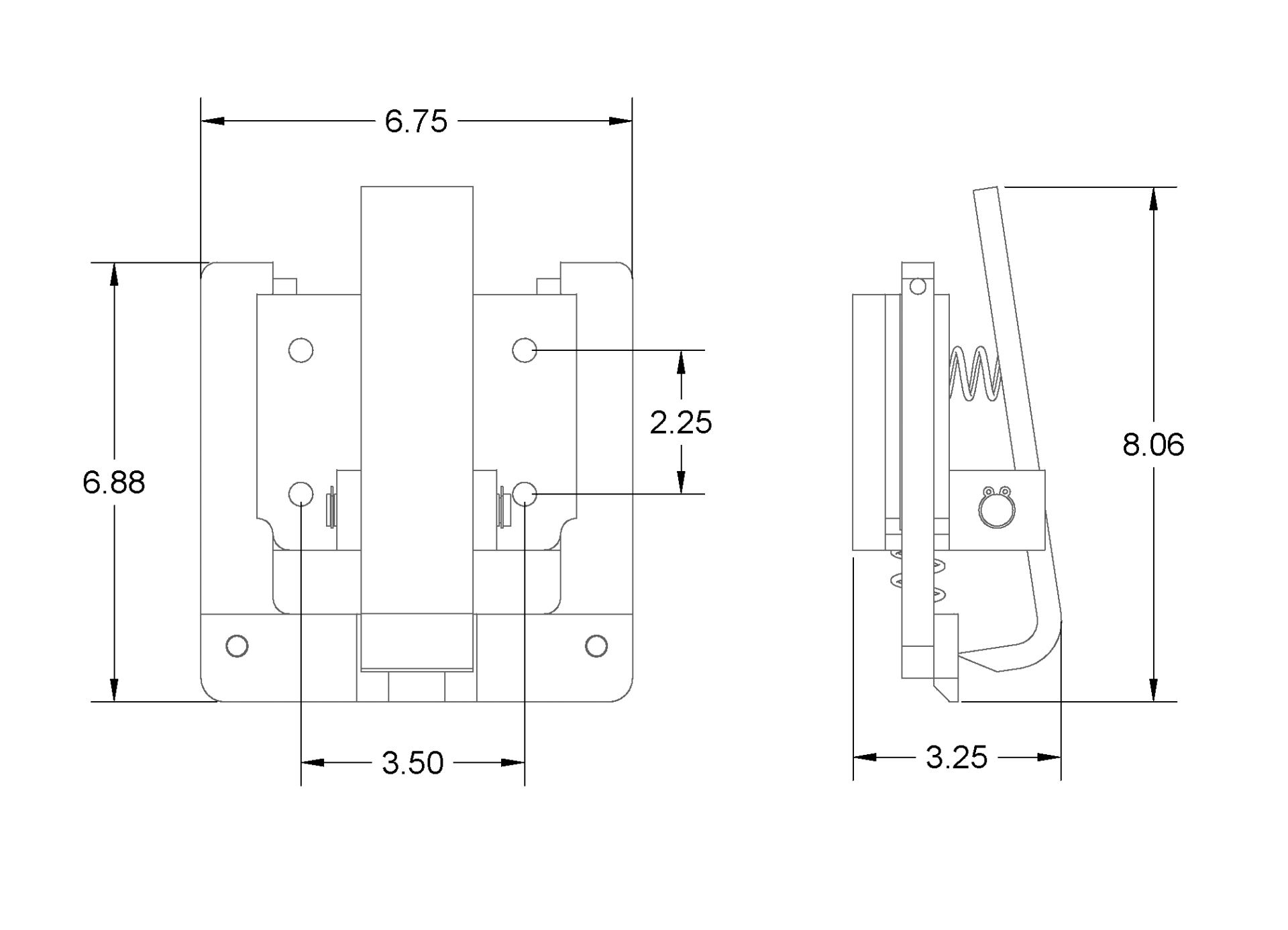

Mounts in a floor cutout between cross members. The trailer floor is routed around the edges of the lock flange for a flush fit. The lock is a lift lay lock built with the same design as dock locks. It’s made of high-strength tempered metal to withstand the impact of containers being moved into place and is zinc-plated for rust protection. It is designed to remain operational with no maintenance. If a lock is damaged, it can be removed and repaired or replaced in a minimal amount of time.

TRAILER FLOOR LOC

The low-profile Trailer Floor Loc is made if aircraft-quality aluminum and mounts directly to the floor for specialty low-profile roller bed systems. The lock has a long life when used as a lock, and not as a stop. Two of these locks will restrain a 10,000 lb. load during normal over-the-road movement on a live roller bed system. Designed for use with low-profile 1-1/2” roller bed systems.